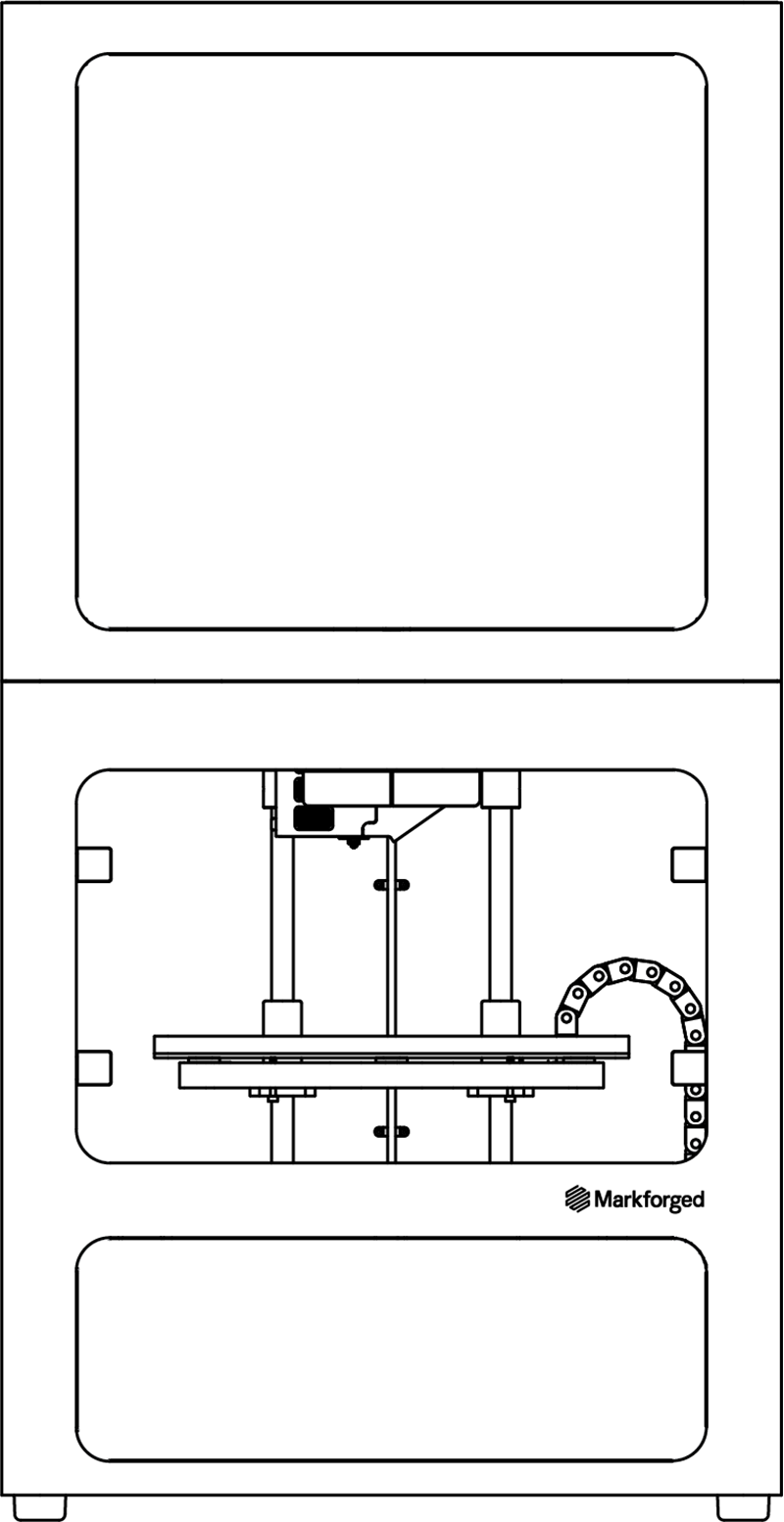

Metal X

The Metal X System is an accessible way to fabricate complex metal parts in a wide variety of advanced metals.

The Metal X

Metals for every job.

Mechanical properties equivalent to cast metal mean you can say goodbye to expensive and long-lead-time tooling for low volume metal parts. Streamline your supply chain and eliminate back-catalog inventory by printing fully functional components on-demand.

Your parts, faster.

Cut mission-critical time out of your development cycle. With ADAM technology, your parts are ready the next day instead of next month. Go straight from CAD to the print all in a compact, clean, and highly affordable platform.

Intuitive Post-Processing.

Metal 3D Printing Walkthrough

Engitype Service Offerings for Markforged 3D Printers

Get your Markforged 3D printers covered under a Markforged Success Plan or Service Plan and you’ll receive exceptional online and onsite service from factory-certified Engitype Service Technicians. Receive the attention and care you deserve as an Engitype partner.

Markforged Success Plan

- Service and Repair Hours 100% Covered

- Hardware Coverage

- Engitype Email and Phone Support

- Engitype Offload 3D Printing Service

No Coverage

- Engitype Email and Phone Support

- Hourly Service Charge

- No Hardware Coverage

- No Engitype 3D Printing Service Access

Get More Information

Download the Markforged – Engitype Success Plan Pamplet for more information.

Technical Specifications

Build Volume

300 x 220 x 180 mm (11.8 x 8.7 x 7.1 in)

Footprint

575 x 467 x 1,120 mm (22.7 x 18.4 x 44.1 in), 75 kg (160 lbs)

Layer Height

50μm and 125μm post-sinter

Print Bed

Heated, vacuum-sealed print sheet, auto bed leveling

Print System

Two nozzles — Metal material and release material

Metal Materials

- 17-4 Stainless Steel

- H13 Tool Steel

- A2 Tool Steel

- D2 Tool Steel

- Inconel 625

- Copper

Ready to add a Markforged 3D printer to your workflow?

We’d love to see which printer would work the best for your business with you.